I have often found myself in a situation where a datasheet states material strength and modulus as flexural or tensile; sometimes both but at other times only one of them.

I find this confusing and decided to research the subject. Here are the results:

The difference between the two testing methods can easily be understood by watching these two short videos. If all is clear to you, just skip the clips and move on.

Video: Tensile

Video: Flexural

This is pretty understandable. But how does it relate to actual values? How close are they to each other? I made a little comparison. In Prospector database you can compare different material properties as a diagram. The options that I chose were injection-mouldable grades (from Albis Plastic Gmbh’s offering), commodity/high-performance, amorphous/semi-crystalline and reinforced/unreinforced. (Albis, incidentally, is a random choice).

How is it with Modulus?

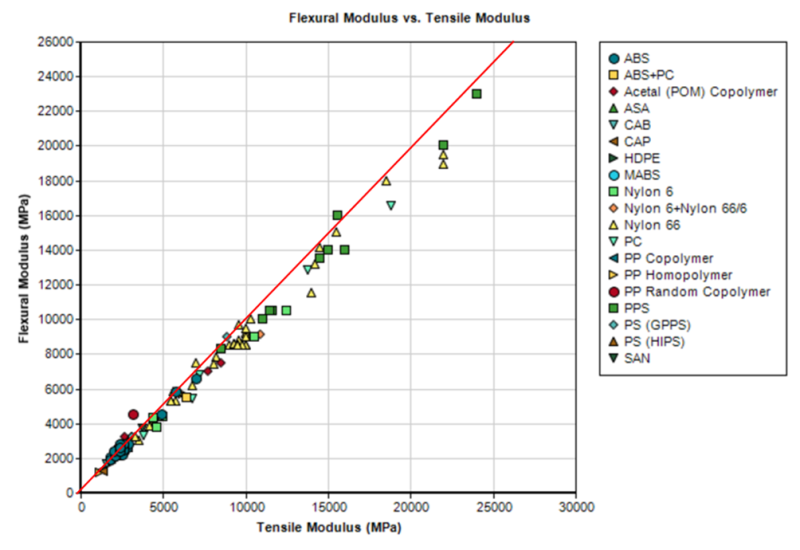

This is how it looks when flexural and tensile moduli are set on the x- and y-axes:

I’ve added a red line to illustrate where the 1:1 ratio would go. As we can see, the values follow the red line relatively closely, confirming that for most polymers, flexural modulus and tensile modulus do not significantly differ from each other. This is in line with my experiences. I would claim that it is possible to compare these two as apples to apples and not go too much astray. It is much more likely that a designer falls into the pothole of considering material properties in room temperature only, as they are usually listed in the datasheets, without taking into account changes due to elevated temperature or moisture absorption.

How about Strength then?

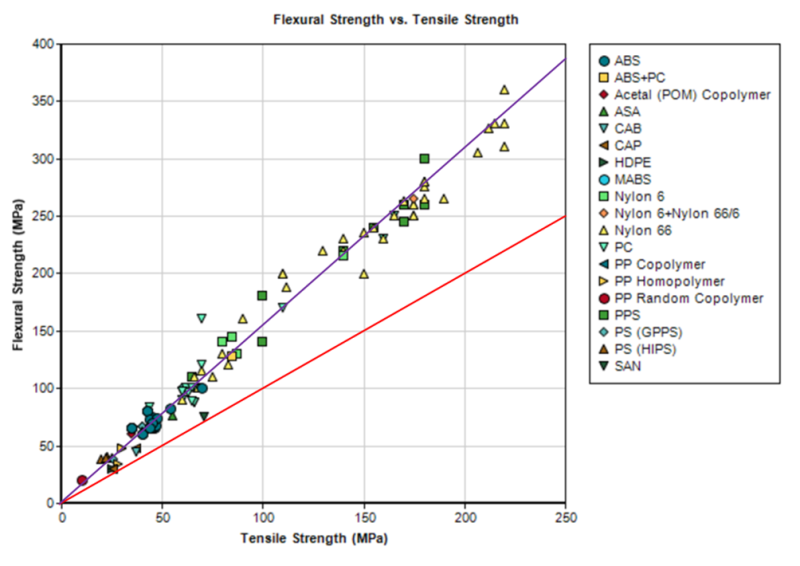

Let’s do a corresponding comparison:

There is more deviation now and the values no longer follow the red 1:1 line. I have drawn a blue line to roughly illustrate the average tendency. It appears that the flexural strength values are roughly 1.5 times higher than the tensile strength values. There are some exceptions and it would be unwise to simplify the case by making it a rule of thumb, but the tendency is probably worth making a note of.

So, which value to use?

In case of clear bending or pulling loads the corresponding values are without a doubt usable. In practice, however, the load is usually some sort of a combination of them, and compression or torsion may be added to the mix. Apart from the load, the geometry of your design is likely to be quite far from a test-lab arrangement. The standardized specimens do not take into account weld-lines or fiber-orientation, either, both of which exist in real products. Plastic product designers should therefore never rely on datasheet values too closely.

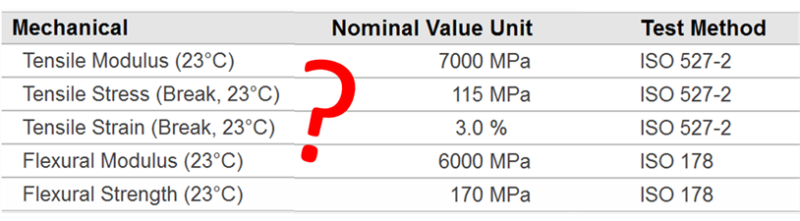

The one most important but often overlooked thing, however, is that the design should meet its long-term use requirements. If elevated service temperature and/or continuous/cyclic loads are expected the strength of your design should be many times higher than what the static strength calculations suggest. For this reason, the decimals do not matter. In calculating the strength in demanding applications I would increase the safety factor by using the lower value, usually the tensile value.