What is Plasticprop.com?

I’ve worked throughout my career in the field of product design, injection moulding and plastic materials. Over the years I’ve been involved in many successful design projects but alongside them I’ve also witnessed numerous unpleasant surprises caused by the unpredictable behaviour of plastic materials. I’ve found making mistakes is very educational.

Disappointing products are one of the main reasons for plastic’s bad reputation. As many as 7 out 10 of plastic products fail prematurely. In most cases, better design and the right choice of material could prevent failures.

In this blog I want to share my own knowledge and experience of how to avoid failures and design functional, durable and thus environmentally friendly plastic products. I welcome all you professionals in this field, both green and seasoned, to share your question and insights.

Let’s make better plastic products together!

Markus Paloheimo, Plastic Product Designer

Plastic Assist Portal

What does a Plasticprop sample tell you about

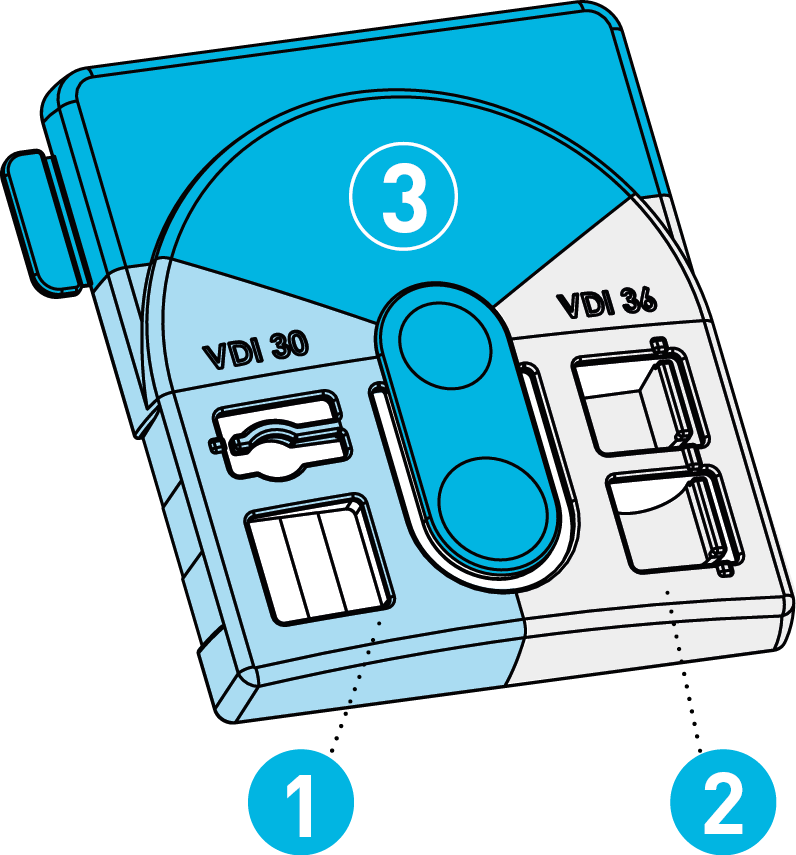

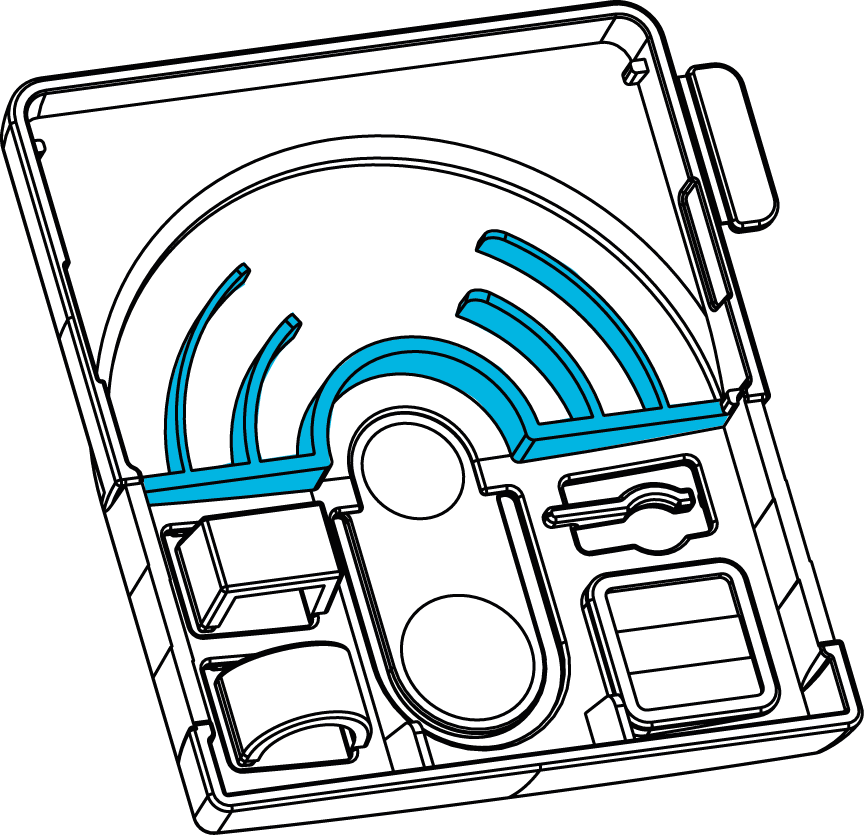

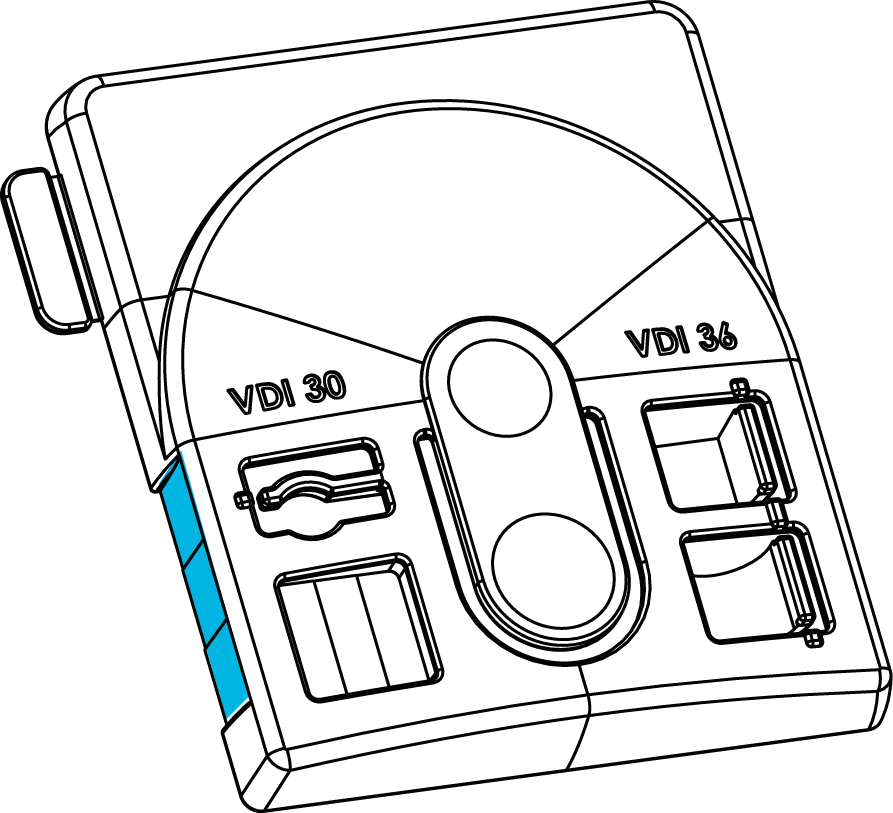

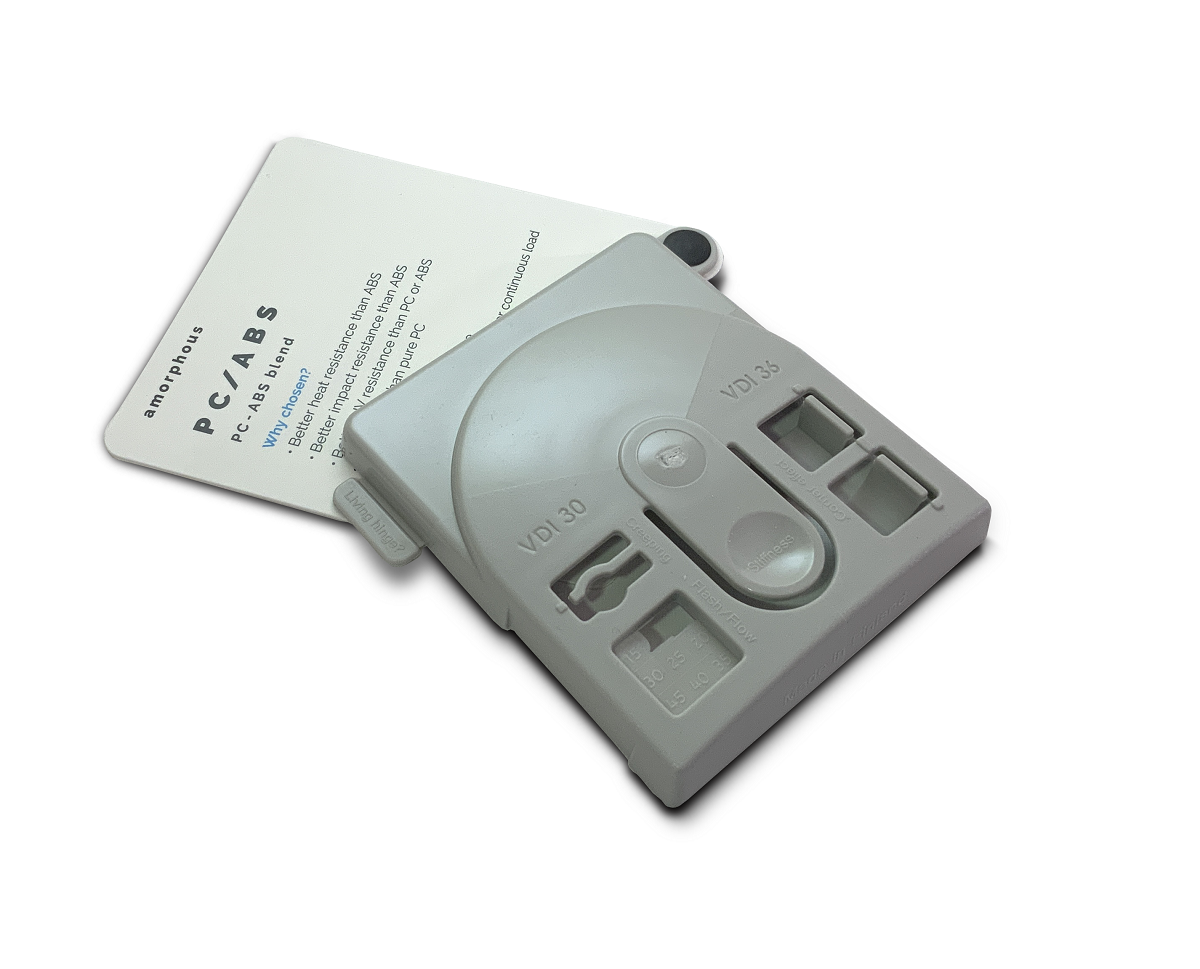

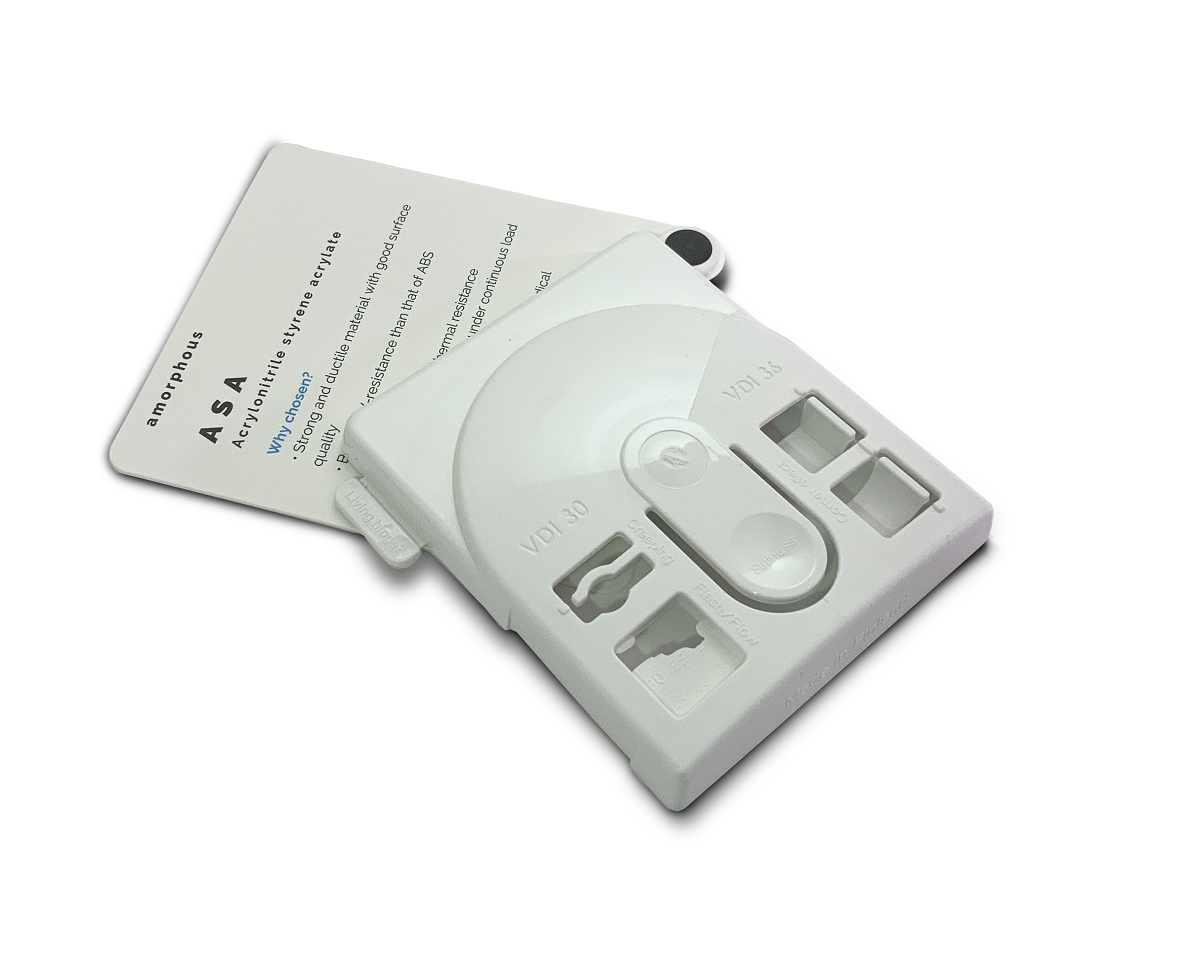

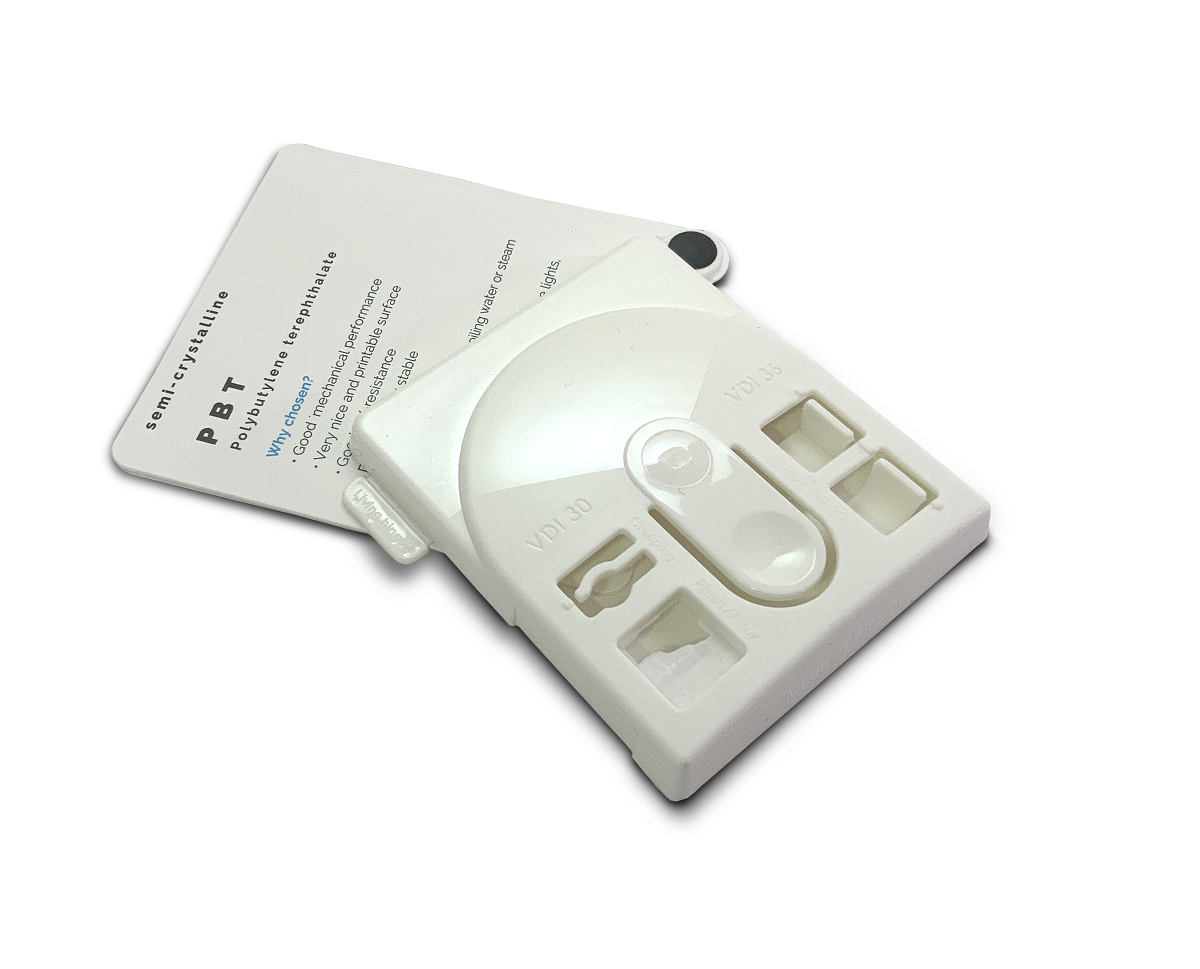

Plasticprop Essentials sample kit

Easy way to explore and compare different plastics hands on: the Plasticprop Essentials sample kit.

The Plasticprop collection of plastic samples was set off by my daily need to assess and compare different plastics in practise. The Plasticprop Essentials contains 20 plastic samples with different characteristics. The set covers a wide range of materials that are commonly used in consumer goods, packaging, kitchen utensils, sporting equipment, vehicles and electronics.

– Markus Paloheimo

Price 295€, vat 0%

Materials in Plasticprop Essentials kit

Positive Plastics samples

The Positive Plastics sample kits introduce a variety of polymers with a reduced environmental footprint!

The three available sample kits include PCR, PIR, bio-based, bio-composite, and mass balanced plastics from various manufacturers. All the materials are injection-mouldable and commercially available.

This is a great tool for understanding the properties of the new sustainable plastics.

Plasticprop.com is in Youtube

Plasticprop material selection guide

For applications that require robustness and ductility, amorphous commodity-plastics apart from HIPS and ABS are a poor choice.

- Back

- Back to Start

Semi-crystalline polyolefins PP and HD-PE are often used for storage boxes, trash-bins, and buckets. They look and feel very similar.

PP is available as a homopolymer and copolymer. The latter has lower strength and modulus but is more impact resistant.

If stiffness is not an important factor, LD-PE might be an option.

Rigid PVC is one of the most used plastics in the world. It is widely used in the construction industry. It includes chlorine which makes it problematic to produce. PVC is not a particularly relevant choice of material for consumer goods.

Examples of applications

Trash containers

ESE, Weber and Sulo, German manufacturers of high-quality trash containers, rely on HD-PE in their products. UV-stabilization appears to be an important sales argument in the trash container business, probably for a good reason. Without any modification, HD-PE is sensitive to UV light. Besides this, the material serves very well for this purpose. It is inexpensive, lightweight, resistant to chemicals and remains tough also in cold conditions.

Lunchbox

Lunchbox material requires FDA food-contact approval and fairly good impact resistance. They typically have some sort of a hinge and a locking mechanism. PP serves well for this purpose.

What do you need from your product?

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

PP and HD-PE both are sensitive to UV light. They are, however, both commonly used in outdoor applications such as garden chairs, trash cans and mailboxes. You can typically notice the difference in their colour after a few years use. Due to developed blockers and stabilizers, however, some manufacturers give their PP products long warranties (10 years and even more), for example, roofing ventilations that are exposed to direct sunshine year-round.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

HD-PE is known for its impact-resistance. It is used, for example, in lower-cost hard hats. If high stiffness is not required, you might also consider LD-PE. It is used in indoor trash cans.

PP is fairly impact resistant, especially if impact-modified.

In some cases HIPS might be an option.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

As you have chosen the commodity path, your expectations cannot be very high. PP is probably your best option, but its suitability to your application in temperature above 90°C must be thoroughly questioned. Anyway, the thermal resistance of PP is better than that of HD-PE or HIPS.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

HD-PE is a safe choice. It’s Tg is -110°C.

Use of PP homopolymer is a risk. It may turn brittle below -10°C. PP copolymer is a better choice.

HIPS is an option as well, although it is difficult to imagine a large box made of HIPS.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

When you need a straight and dimensionally accurate product with shiny surface, you are more likely to find the material within the amorphous options, such as PS and SAN.

- Back

- Back to Start

HIPS is more ductile. The butadiene particles compounded to PS improve its impact resistance significantly.

ABS is relatively inexpensive and therefore also sometimes listed as one of the commodity plastics.

Examples of applications

Fire detector housing

In many countries, a fire detector in every room is required by law. The size of the market has pushed the cost of the product down.

The housing does not have any challenging mechanical functions. It just has to hang on the ceiling, hold the battery and cover what is inside the device. Typically the material used is PS. ABS or HIPS could be used as well in case of a need for improved impact resistance.

Toy guns

Toy guns are a typical application for PS. Everybody with kids knows that the lifetime of such products is typically short. PS is brittle.

In moving parts, the user often experiences undesirable sticky friction, which is typical for amorphous plastics.

ABS would be a better choice for toy guns but unfortunately, the cost seems to be a more important driver in this category than quality.

Computer keyboard

A computer keyboard does not sound like a commodity product, but the cost pressure is high in all consumer electronics.

The back panel of a keyboard is not subjected to chemicals (hand lotion, nail polish remover, potato chip oil) the same way the front panel is. It is a relatively large component that requires dimensional accuracy and a certain level of impact resistance. The back panels are often made of HIPS.

The keys in higher-quality keyboards, by the way, are made of PBT, a semicrystalline plastic with good wear resistance, chemical resistance, and low coefficient of friction

What do you need from your product?

Glossy surface

If you need a glossy and shiny surface your choices are limited to PS and SAN.

If you afford to pay slightly more, ABS is fairly inexpensive.

The surface of PP with properly polished mold is good, although a little oily and sensitive to scratching.

The EPDM particles in HIPS always turn the surface slightly matt.

PP, filled with talc or natural fibers, might provide a nice, but not glossy surface.

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

As the name High Impact Polystyrene indicates, the impact resistance of HIPS is high. Another good option is ABS: in some cases it is classified as a “commodity plastic” due to its relatively low cost.

SAN and PS as general purpose grades are a bad choice in terms of impact resistance.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

If you are looking for a commodity plastic, your expectations for UV resistance cannot be too high.

ASA would be an option, if you are ready to pay a little more. PS, HIPS and SAN are all sensitive to UV light.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

As you have chosen the commodity path, your expectations can not be very high. If the required continuous service temperature is above 70°C it is unlike that you’ll find an appropriate material within commodity plastics.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

PS and SAN are both used in freezer boxes. Many of us have witnessed in practice how these do not resist impacts very well.

Since you don’t need transparency, ABS (sometimes classified as commodity plastic) or HIPS would be a better option.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

Straight or ductile?

- Straight

- Ductile

- Back

Choose Straight for straight edges, shiny surface and dimensional accuracy.

Choose Ductile for mechanical functionality, impact-resistance, and robustness.

Amorphous plastics are not mechanically well-performing or chemically resistant. A low-cost transparent plastic has even poorer qualities.

- Back

Two common amorphous transparent commodity plastics are PS and SAN. PMMA is also in some instances classified as a commodity plastic.

Amorphous transparent PET (APET, A-PET) is used in the preforms of blow-molded PET-bottles. Its heat resistance is poor, which you can experience by filling a soda bottle with boiling water.

PP Random Copolymer (PP-RC), is also a commodity plastic and a semi-crystalline exception among the amorphous alternatives. It is always at least slightly milky but has many advantages (chemical resistance, ductility, use of integral hinge) most of the amorphous materials do not offer.

Examples of applications

Packages

Despite its limitations in clarity, the most common transparent plastic in sales packages is PP-RC. One of its advantages is the utilization of the integral hinge. The lid and the bottom of the package can be made as one component.

FDA approved PP-RC grades are also widely used in the food industry.

Refridgerator boxes

Refrigerator boxes are made of commodity plastics PS and SAN. The thickness of their walls is often inadequate which makes them break very easily. Using SAN instead of PS (better impact resistance, slightly higher cost) and increasing wall thickness would make the boxes more durable and therefore more sustainable.

The lids of the boxes are often made using the same materials opaque.

Tableware

Transparent disposable drinking glasses are usually made of PS. Sometimes PP-RC is used as well. When thin-walled, its clarity is reasonably good and it would be easier to recycle.

SAN, with higher wall-thickness, is used in water jars and impact resistant plastic champagne glasses.

Candystore displays

The displays in candy stores are typically PMMA. In this use, its chemical resistance suits the purpose well.

What do you need from your product?

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

PS is very brittle and HIPS cannot be used because it does not come in transparent form.

SAN is slightly more ductile but cannot be described as impact resistant.

Reasonably cost-efficient PMMA is fairly brittle as well, although the transparent protectors around an ice-hockey rink are made of thick PMMA plate. High wall-thickness helps, but increases material consumption and production cycle time.

If you can accept the limitations in transparency, PP-RC might be a good choice.

If you need improved impact resistance, you have to take a look at the materials on the next cost level. MABS or SBC might be considered.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

PMMA, ofthen classified as commodity plastic due to its relatively low cost, is known for its good UV resistance. It is used on boat windows.

PS and SAN can not be recommended for long UV light exposure. PP-RC is not a good choice either.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

As you have chosen the commodity path, your expectations cannot be very high.

The thermal resistance of PS, SAN, PMMA and A-PET is low.

Semi-crystalline PP-RC is a better choice, although its thermal resistance is not very high either, if compared to engineering plastics such as PA or PBT.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

PS and SAN are both used in freezer boxes. Many of us have witnessed in practice how these do not resist impacts very well.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

Does the component need to be transparent?

- Transparent

- Opaque

- Back

If so, choose Transparent.

If not, choose Opaque.

You need a rubbery material but the application you are working on is cost-sensitive.

- Back

The lower-cost members of the thermoplastic elastomer (TPEs) family might be considered. They include TPE-S (SEBS and it's cheaper version SBS) and TPE-O.

Some thermoplastics outside the TPE family, such as LD-PE, EVA and soft PVC, can also be considered soft or rubbery.

Examples of applications

Rubbery laundry baskets

Rubbery laundry baskets are made of TPE-O.

Freezer box lids

Freezer box lids require a certain degree of elasticity in subzero temperature. LD-PE is typical choice for this purpose. The Tg of LD-PE is app. -110°C.

What do you need from your product?

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

Improved impact resistance is one of the main reasons components are made of soft materials or covered by them. Impacts may, however, crush or rip the component.

A properly working shock-absorber requires a good combination of thickness and hardness.

TPE-O is used in car bumpers.

LD-PE is used in traffic cones and rubbish bins.

EVA is used in shoe midsoles.

Soft PVC is used in beach sandals

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

The lower cost TPE grades TPE-S, TPE-O and TPE-V are all fairly resistant to UV light – UV-modified TPE-S in particular.

It is essential not to confuse the two members of the TPE-S family, SEBS and SBS. UV resistance of SBS is poor.

LD-PE can not be recommended either. EVA is probably a better choice.

Soft PVC is used on boats. When modified its resistance against UV light is good.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

As you have chosen the commodity path, your expectations cannot be very high. When it comes to thermal resistance, TPE-S is not the strongest choice among the TPE family. Very high thermal resistance cannot be expected of it.

You might need to take one step up to TPE-V.

LD-PE and EVA do not perform well in a temperature above 60°C. Soft PVC is not a good option either.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Fire retandancy

Soft PVC is a common choice in the construction industry because of its self-extinguishing behaviour. If the ignition source is withdrawn it will stop burning.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

Low service temperature is not a big issue when selecting a lower cost rubbery material. They all endure cold conditions rather well.

TPE-S contains oil, and in the case of some less advanced grades, the oil might migrate to the surface of the product in long-term cold conditions.

The Tg of LD-PE is around -120°C.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

Extreme flexibility

When extreme flexibility is needed, your choices are limited.

At its softest TPE-S is like a flexible gel. For normal applications, its flexibility is usually adequate.

TPE-V is available relatively soft as well, from Shore-A 40 and above.

The hardness of EVA and LD-PE is typically measured on the Shore D scale.

In this article, you can read more about the subject.

Do you want your component to be rubbery or hard?

- Rubbery

- Hard

- Back

Choose Rubbery for elasticity, flexibility or soft touch.

Choose Hard for stiff and rigid.

When designing parts with demanding technical functions, both mechanical and service environment-related, semi-crystalline materials are typically a good choice. Their ability to withstand continuous load, fatigue, wear, and lubricants are superior compared to amorphous plastics. Levers, gears, cams, wheels, pulleys, etc. are usually made using semi-crystalline plastics.

- Back

- Back to Start

The most typical materials used in machine design are POM and different polyamide grades, such as PA6, PA66, and PA12. Other good options are from the polyester family: PBT and PET.

PP is an affordable commodity plastic, but in many cases, its versatile qualities might offer a valid option for applications that do not require high strength, stiffness or thermal resistance.

When mechanical requirements are limited to impact resistance and chemicals are not involved, amorphous plastics ABS, PC or PC/ABS can be the best choice.

Alloys of semi-crystalline and amorphous plastics, such as ABS/PA or PC/PBT, can be tailored in an attempt to combine the best qualities of both material groups (which includes the risk of combining the worst).

Technical does not automatically equal poor appearance. With proper design and appropriate tooling/process, the result can be visually very pleasing using semi-crystalline materials. Making amorphous materials withstand continuous load or chemicals is a harder task.

Examples of applications

Chain saw and lawn-mower housings

The housings of chain saws and lawn-mowers do not carry much weight but they must be tough and resistant to oil and gasoline as well as UV-light. They also need to have a relatively high quality appearance.

The plastic used is typically PA6/PA66.

ABS is such a common choice for lawn-mower decks, that manufacturers must have validated its chemical resistance to be sufficient.

Side release buckles, plastic zippers

Side release buckles require low friction and good resistance against fatigue and continuous load. These are all properties of semi-crystalline plastics, especially POM.

Due to the low friction properties, injection-molded plastic zippers are made of POM as well. Plastic zippers are also produced by “coiling” a plastic monofilament to form the teeth. This type of zippers are called “Nylon Coil” zippers, although PA is today mostly replaced by polyester, assumingly PBT.

Electrical connectors, relay sockets and switches

Compared to the other semi-crystalline engineering plastics, PBT offers the best dimensional stability. It does not absorb moisture as PA does.

If switches or relay socket require higher strength and stiffness, PBT may be reinforced with glass.

Helmet

The materials used in helmets must have good toughness so they do not crack, and high strength to take the high load without deforming.

Hard hats, used in constructions, are typically made of ABS. It retains its impact resistance in cold conditions better than PC, which is a more common choice in bicycle and motorcycle helmets.

Helmet is a good example of a technical and demanding high-quality product that is made of amorphous plastic.

Ice-hockey helmets are typically made of HD-PE.

More

What do you need from your product?

Low friction

The surface of many semi-crystalline plastics like PP, PA66 or POM is slippery, even oily, to touch. POM is the most common choice for low friction applications. Different PA grades are typical as well.

In demanding applications, polymers can be filled with oil or PTFE to achieve low friction.

Two important factors in your application are surface pressure (P) and sliding velocity (V). If P*V is very high, the surfaces will inevitably heat up. You have to make sure the chosen material can withstand this. Semi-crystalline high-performance materials like PEEK or PPA may be an option.

In case you are planning to use amorphous plastic, it is highly recommended to study its friction properties beforehand.

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

All the engineering plastics, semi-crystalline and amorphous, witness some level of plastic behaviour. This indicates that they are not brittle.

If the mechanical challenges are limited to impacts (no chemicals, continuous load or wear) amorphous options like PC, PC/ABS (and other PC alloys) or ABS might be a good choice.

Semi-crystalline options PP, PA6/66, PA12, POM and PBT are all reasonably ductile. Their other qualities probably have bigger influence in the final material selection.

An impact-modified grade is available for most materials.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

High quality appearance

When visual high-quality is needed, designers often prefer amorphous plastics. If the mechanical challenges are limited to impacts and short term-stresses, common housing plastics, such as ABS, ABS/PC or PC, fulfill the purpose. However, if resistance against fatigue, stress-cracking or wear are needed, you are likely to find a more suitable plastic within the semi-crystalline offering.

When properly designed, the following materials can deliver pleasing visual quality together with mechanical performance and chemical resistance (in preference order).

- PBT

- PA6

- PA12

- PA66

- PC/PBT alloy

- PP

Compared to amorphous materials, semi-crystalline plastics have a higher and uneven shrinkage, which results in more pronounced warpage and sink-marks. It is therefore important to follow the basic principles of plastic product design: uniform wall thickness, sufficient radius, and rib thickness guidelines. From a tooling perspective, a well-defined parting line, proper cooling, and a properly positioned injection system are vital.

Fatigue resistance

Fatigue is a phenomenon that plastic designers should always take into account. The effects of fatigue do not show in the short term use. A component might withstand 100 cycles with no visible effect but suddenly fail after 15 000 cycles.

POM is known as a “spring plastic”. It endures fatigue well.

All the polyamides are also highly fatigue resistant.

PEEK is a high-performance material but has excellent fatigue resistance at room temperature as well.

To avoid fatigue, a component should be designed so that the repeating stress is significantly smaller than the tensile strength of the material, approximately 10-20%.

Resistance to continuous stress

Stress-cracking is the most common reason for plastic components to fail their purpose.

Semi-crystalline materials endure continuous stress far better than amorphous materials. POM, PA, PBT, and PP are good options if long term stress is expected.

To avoid stress cracking, the product should be designed to endure significantly higher stress than short term experiments indicate. Semi-crystalline materials endure continuous stress better than amorphous materials.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

PA6 or PA12 are better choices than PA66. PBT is another good option. The UV resistance of POM is poor.

On the amorphous side ASA is the preferred choice. Oddly PC/ABS is more resistant to UV than PC or ABS.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

PA66 is probably the best choice.

It is good to note that the heat resistance of POM is not very high.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

The Tg of POM is app. -75°C so it should retain its ductility well in cold conditions.

In subzero temperature PA and PBT are clearly below their Tg but are typically still fairly ductile, especially if compounded for this purpose.

With PP you have to be careful. PP homopolymer has Tg of -10°C and PP copolymer -20°C. Below this they might turn brittle.

In cases, with no risk of high continuous loading or chemicals, amorphous ABS, PC or PC/ABS (or other PC alloys) might be an option.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

In a harsh service environment, the common engineering plastics such as POM, PA or PBT will not necessarily perform as required. In such cases, high-performance plastics are a good choice.

- Back

- Back to Start

The common semi-crystalline high-performance plastics include PPA, PPS, and PEEK. The advantage of high-performance plastics is their ability to retain their mechanical qualities in considerably higher temperatures - 150 °C and above - than normal engineering plastic. Their chemical resistance is also excellent and many of the materials are self-extinguishing.

Fluoropolymers PVDF, PFA, FEP, ETFE have extreme chemical resistance, low friction and are the only plastic material group that is practically immune to UV-light. The best-known fluoropolymer PTFE (Teflon) in not injection moldable, but demonstrates well the unique qualities of the material group.

Amorphous high-performance plastics, such as PSU, PES, and PEI are typically chosen due to their dimensional accuracy, electrical insulating properties, and resistance to hydrolysis. They do not serve well in functional, moving, and load-carrying machine parts.

Examples of applications

Aviation industry

The aviation industry follows extremely strict fire retardancy requirements. Many of the high-performance materials are inherently self-extinguishing and fill the UL-94 V0 requirement.

If you look around in an airplane, you can find very expensive light switches and other components of the passenger service units.

What do you need from your product?

Resistance against hot water and steam

Amorphous high-performance materials, such as polysulfones PSU, PPSU, and PES, are typically used when good dimensional accuracy and high strength are needed under exposure to hot water and steam. They do not, however, are not a good choice for moving components of a mechanism.

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

When it comes to impact resistance, PPA and PEEK are at least on the same level as more common engineering plastics PA6, POM or PBT.

An impact-modified grade is available for most materials.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

Low friction

Two important factors in your application are surface pressure (P) and sliding velocity (V). If P*V is very high, the surfaces will inevitably heat up. You might need a high-performance plastic like PEEK or PPA to withstand the temperature. PEEK especially is known for its good bearing properties.

In demanding applications, polymers can be filled with oil or PTFE to achieve low friction.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually. The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

Fluoroplastics, such as FEP, PFA, ETFE, and PVDF have many advantages. Excellent UV resistance is one of these. From the same perspective, PPS is typically classified as “good” and PEEK, PPA and PEI as “fair”.There are exceptions and this varies depending on the grade.

Amorphous high-performance plastics do not endure UV-light well.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

A commonly used definition for high performance plastics is that they have a permanent operating temperature of more than 150°C. They are resistant but not immune to high temperatures. The effect in their mechanical performance cannot be overlooked.

Semi-crystalline PPA and PEEK are favoured in machine design applications that require substantially high resistance against heat.

Amorphous polysulfones, such as PSU, PPSU and PES are chosen primarily in cases where the component is subjected to hot water and steam.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

Typically, high-performance plastics are used due to their ability to withstand high temperatures. In cold temperature they should behave like all other plastics – sufficient ductility in cold must be confirmed by testing.

The Tg of semi-crystalline high-performance plastics is high, crossing it in subzero temperature should not be a concern.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

Will your product be subjected to extreme conditions?

- High-performance

- Normal

- Back

Choose High-performance for high temperature (150C° and above), aggressive chemicals, boiling water/steam or high fire resistance.

If not, choose Normal.

Adding reinforcement, typically 15-40 % (in some cases even up to 60 %) of glass, to plastic can significantly improve the strength, thermal resistance, and stiffness of the product. It also improves chemical resistance but not necessarily impact resistance.

- Back

- Back to Start

Reinforced parts are usually the functional components of heavy-duty products and made of semi-crystalline plastics like PA6+GF, PA66+GF, PET+GF or PBT+GF.

Amorphous plastics with reinforcements, such as PC+GF is sometimes used in boxes that require, in addition to impact resistance, extremely high strength.

The most common reinforcement by far is glass fiber. Carbon fiber is an attractive filler, but considerably costlier than glass and therefore usually used in high-end applications only.

In this section, you can find the following reinforced engineering plastics:

Examples of applications

Power tool housings

Power tool housings must transfer the torque from the engine to drill/screw. Today even battery-driven devices are so powerful, that it requires a lot of effort to hold the tool still. Some tools also have a hammer-action that requires impact fatigue resistance from the construction.

If you find old tools from the ’80s or ’90s, you may notice that using PC or PC+GF in the housings was quite common. In the construction site, tools may be subjected to paint, turpentine, glue or oil. This requires chemical resistance. It is also good to notice, that the screw bosses always cause continuous stress of some level. Semi-crystalline plastic is a safer choice.

Commonly used plastic in power tool housings is PA66+30GF, often with TPE-S 2K soft grip.

In smaller and less powerful hobby applications PC might still be used.

Tool handles

Garden and construction tools require high strength, ductility, and stiffness.

Lower cost tools may be made of PP+GF. The outcome is not as stiff as it would be with PA+GF, this naturally depends on the geometry of the product. If the handles bend, some of the working energy is lost, which makes the tool less efficient.

Impact modified PA6+30GF is quite typical material in tool handles. It does absorb some moisture. If you compare an indoor stored and outdoor stored tool, you may notice a difference in their bending resistance.

The use of long-fiber materials, both PP and PA, is increasing in branded high-quality tools. They do not significantly increase the stiffness of the product, but strength, impact strength (especially in cold conditions) and fatigue resistance are considerably improved.

Under the hood -applications

Reinforced semi-crystalline engineering plastics offer good strength, heat resistance, and chemical resistance.

PA66+GF is a common choice in under the hood -applications. Sometimes its performance is not sufficient in challenging thermal or chemical conditions. In such cases, high-performance plastics such as PPA+GF and PPS+GF are used instead. These can be found by taking one step back and proceeding the high-performance path.

PBT+GF is a valid engineering plastic with relatively similar properties to PA+GF. However, in the automobile industry, PA+GF is preferred in applications that are subjected to heat, trembling, and oil. In cars, PBT+GF used in electrical connectors, lighting, and interior components.

PP+GF (with long or short fibers) is widely used in the automotive industry, but its thermal properties are not sufficient near the engine.

What do you need from your product?

Strength and modulus

Very commonly used glass content with engineering plastics is 30%. Compared to unfilled plastics the product becomes considerably stiffer and stronger yet is still relatively easy to process.

Please see below the mechanical properties of PBT with different glass contents. The values are extracts from material datasheets and should be considered as theoretical. In practice, service conditions, fiber orientation, and weld lines may reduce them considerably.

PBT+0%GF

- Yield stress 60 MPa

- Tensile modulus 2,7 GPA

- Strain at yield 8%

PBT+20%GF

- Stress at break 120MPa

- Tensile modulus 7,5 GPa

- Strain at break 2,7 %

PBT+40%GF

- Stress at break 145 MPa

- Tensile modulus 12 GPa

- Strain at break 2,3%

An increase of 10% in the fiber content, can improve strength and modulus by 20-35%. It is good to bear in mind, that the same can easily be achieved by modifying the geometry of the component. When the height of a bent element is increased slightly (for example from 10 mm to 11 mm) its stiffness may be improved correspondingly.

It is not rare to use 40% or even 50% glass content in demanding applications. Engineering plastics with up to 60% glass content are available, but not commonly used due to processing difficulties.

If cost is not an issue, carbon fibers lead to higher strength and modulus. In comparison:

PBT+40%CF (CELSTRAN PBT-CF40-09)

- Stress at break 175MPa

- Tensile modulus 14,5 GPA

There is also an increasing number of LGF (long glass fiber) materials available (mostly PA and PP). Compared to short fibers, long fibers increase material strength but their main advantage is improved impact resistance. The effect on modulus is minimal.

The highest modulus value found in the Campusplastics.com database is provided by Celstran PPS-CF50-02 AF3002 Natural, PPS with 50% long carbon fiber content. Its tensile modulus is above 40 GPa and Stress at break 155 MPa.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually.

The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

Reinforced plastic components are typically black, which is good in terms of UV light. Reinforcing blocks some of the UV light.

PA6+GF is a safer choice than PA66+GF.

PBT+GF is another prefered option.

PP+GF or POM+GF are not good choices.

Reinforced amorphous plastics such as PC+GF or ABS+GF cannot be recommended either.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

Reinforcements, glass or carbon fibre are not as sensitive to heat as the base material. Therefore, reinforcements increase the heat resistance of all plastics.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

If you place Plasticprop samples made of PA6+30GF and PBT+30GF in an oven and heat them to 130°C, you can clearly notice that they both get remarkably softer, but it is difficult to tell the difference. PA is, however, a more common choice in high heat application, such as car engines. PA66 endures heat better than PA6.

If you do the same study with a PP+30GF sample, you will notice that the material is very close to its service temperature limit.

If the long-term service temperature will exceed 120°C, I recommend you take one step back and follow the high-performance path.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

PA+GF and PBT+GF both behave reasonably well in sub-zero temperatures.

If you consider using PP+GF, please note its Tg, app, -20C°. Crossing this may cause a significant change in material behaviour.

Long glass fibre (LGF) increases impact resistance significantly especially in cold conditions.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

Reinforcing plastic increases its strength and modulus. Due to the increase in modulus; however, the material toughness is decreased which might lead to lower impact resistance. In some cases, on the other hand, fibres prevent cracks from propagating. To improve impact resistance, you need high glass content. Adding a mere 15% glass, for example, probably only makes the product more sensitive to impacts.

Polyamide (PA+GF) is a common choice when both strength and stiffness are needed in combination with good impact resistance. For example, the injection-moulded shaft of an axe is commonly made of PA6 +30-40% GF.

Other reinforced semi-crystalline engineering materials (PBT+GF, POM+GF) are also reasonably impact-resistant. PP+GF is an option for cost-sensitive applications.

Unfilled PC is very impact-resistant. It is usually filled to increase strength and stiffness. Reinforcing may decrease its notch-sensitivity and therefore also makes it more impact resistant in some cases.

Carbon fibre is more expensive than glass fibre and makes the product stronger and stiffer, but more fragile.

Long-fibre (LF) materials increase impact resistance significantly. They also help in retaining impact resistance in low temperatures. Long fibre are used mainly with PP and PA.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance. This is particularly the case with PP+GF.

Read more about how to design impact-resistant plastic products.

Glass- or carbon-fibers improve the strength and modulus of plastics considerably, as well as their thermal and chemical resistance. In a harsh service environment, however, common reinforced engineering plastics such as POM, PA or PBT may not perform as required. In such cases, reinforced high-performance plastic is a good choice.

- Back

- Back to Start

The common reinforced semi-crystalline high-performance plastics include PPA+GF, PEEK+GF, and PPS+GF. Their mechanical qualities are good, but they are still within the same performance range with basic engineering plastics. The advantage of high-performance plastics is their ability to retain those qualities in considerably higher temperatures, 150 °C and above. Their chemical resistance is also excellent and many of the materials are self-extinguishing.

Amorphous high-performance plastics, such as PSU, PES and PEI are available glass-reinforced as well. They are strong and rigid, but more importantly, dimensionally accurate, resistant to hydrolysis, and offer good electrical insulation.

The most common reinforcement material in plastics is glass fiber. In high-performance plastics, carbon fiber is not rare, either.

In this section, you can find the following reinforced high-performance plastics:

Examples of applications

Under the hood -applications

The properties of common reinforced engineering plastics are often not sufficient in the “under the hood” applications of the automobile industry. In such cases, high-performance plastics such as pPA+GF, PPA+GF (load-carrying components) and PPS+GF (chemical resistance) are used instead.

Aviation industry

The aviation industry follows extremely strict fire retardancy requirements. Many of the high-performance materials are inherently self-extinguishing and fill the UL-94 V0 requirement.

If you look around in an airplane, you can find very expensive light switches and other components of the passenger service units.

What do you need from your product?

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop or be mishandled during transportation.

Reinforcing plastic increases its strength and modulus. Due to the increase in modulus; however, the material toughness is decreased which might lead to lower impact resistance. In some cases, on the other hand, fibres prevent cracks from propagating. To improve impact resistance, you need high glass content. Adding a mere 15% glass, for example, probably only makes the product more sensitive to impacts.

When it comes to impact resistance, pPA+GF, PPA+GF and PEEK+GF are at least as good as the more common engineering plastics PA+GF or PBT+GF. However, it is good to consider that PPS+GF is very brittle.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

UV-resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually.

The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

Reinforced plastic components are typically black, which is good in terms of UV light. Reinforcing blocks some of the UV light.

When it comes to UV resistance, PPS and PEEK are typically classified as “good” and PPA and PEI as “fair”. Amorphous high-performance plastics do not endure UV light well.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in elevated service temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

A commonly used definition for high performance plastics is that they have a permanent operating temperature of more than 150°C. They are resistant but not immune to high temperatures. The effect in their mechanical performance cannot be overlooked.

Reinforcements of glass or carbon fibre are not as sensitive to heat as the base material. Therefore reinforcements increase the heat resistance of all plastics.

Semi-crystalline PPA+GF, PEEK+GF are typical choices for machine design applications. PPS+GF is probably chosen more often for its chemical resistance than its thermal resistance.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

Typically, high-performance plastics are used due to their ability to withstand high temperatures. In cold temperature they should behave like all other plastics – sufficient ductility in cold must be confirmed by testing.

The Tg of high-performance plastics is high, crossing it in subzero temperature should not be a concern.

Long glass fibre (LGF) increases impact resistance significantly, especially in cold conditions.

Discuss the matter with your material supplier. A product that is especially tailored for cold environments is probably available.

If you have any doubts, it is essential to test in practice. Explore reference products to confirm.

You need high strength and stiffness. The performance and durability of your product are highly dependent on its service environment. Is your product subjected to extreme conditions?

- High-performance

- Normal

- Back

Choose High-performance for high temperature (150C° and above), aggressive chemicals, boiling water/steam or high fire resistance.

If not, choose Normal.

Does your component need to bear high loads without breaking or bending?

- Reinforced

- Unreinforced

- Back

Choose Reinforced for high strength, high modulus, or metal replacement.

If not, choose Unreinforced.

When visual qualities are emphasized amorphous materials usually deliver them. Due to their low and even shrinkage straight and dimensionally accurate parts are easier to process. They also have a visually pleasing surface finish that can, if needed, look shiny.

- Back

- Back to Start

The commonly used materials for visual components are ABS, PC, and their alloy PC/ABS. In lower cost and less demanding applications, you might find HIPS.

In the drop-down boxes below you may find ASA, PPO and some other alternatives.

Please bear in mind the limitations of amorphous plastics, however. They are prone to chemicals, fatigue, and stress-cracking.

Visual parts are often used for covering the inside of a device where the technical components take care of the technical functions. In many cases, this is a good principle.

When you have gone through the selection criteria, you may reconsider the use of amorphous plastics. The best compromise between visual and technical qualities is introduced in the technical path.

The common visually strong plastics inc:

Examples of applications

Mobile phone covers

Mobile phone covers and housings are made of PC or PC/ABS. They deliver dimensional accuracy, high-quality appearance, good impact strength, and relatively high modulus. Their chemical resistance is not very good, however, and considering that they are subjected to sun-lotion, oil, grease, nail polish remover, urea, chili, etc., it is actually quite surprising that they survive the lifetime of a phone, up to seven years. They must have been designed with stress-cracking in mind: in a way, that continuous stress does not occur.

Mobile devices tend to heat up in active use. ABS is probably avoided for this reason.

Lego blocks

Commodity plastics, such as PS, are a common choice in cheap toys which unfortunately very often results in brittleness and a short lifespan. Due to their high quality, I consider Lego blocks are engineering products.

Lego uses huge amounts of ABS in the production of its famous building blocks. They need to be dimensionally accurate, straight and tough, which could hardly be achieved with any lower-cost material (although ABS is often classified as a commodity plastic due to its relatively low cost). The transparent components are made of PC.

Lego must have a sophisticated quality-system as they manage to keep the grip between the blocks similar despite the difference in size and shape or production year and site.

Lego has invested heavily in order to replace the normal oil-based plastic grades with more sustainable plastics that should “offer the same safety, quality, durability and play experiences as our current materials.” (www.lego.com). One can only hope that such a challenge can be met.

TV remote controller

The housings of TV remote controllers are typically PC/ABS. The combination of improved impact resistance (PC) and chemical resistance (ABS).

You might have noticed that the snap lock on the battery lid is often broken, which easily happens if any continuous stress is subjected to the element.

WiFi router housings

WiFi routers can be hidden but as high-tech devices, they must express high quality. They are not handled with dirty hands or stressed, and subjected to moderate heat, so ABS is usually used.

What do you need from your product?

Impact resistance

Impact resistance of the product is always good to keep in mind. Even if your product is not subjected to impacts in its intended use, it might fall, drop, or be mishandled during transportation.

Visual appearance is not difficult to combine with good impact resistance. From this perspective PC is especially strong, but ABS, PC/ABS (and other PC alloys) and PPO are good as well. In some cases HI-PS might be an option. You can find it by choosing the commodity path.

An impact-modified grade is usually available for every plastic material.

Avoid sharp inner corners whenever you can. This cannot be stressed too much.

Wall thickness has an effect on the impact resistance of a component.

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer. However, they also lose some of their toughness and turn more brittle. This will affect their impact resistance.

Read more about how to design impact-resistant plastic products.

Performance in elevated temperature

It is important to bear in mind that elevated temperature has a significant effect on the strength and modulus of plastic materials.

Please note that at the upper end of the service temperature range, the material properties differ significantly from properties at room temperature.

When visual qualities are emphasized in the material selection process, the product is not likely to be used in very hot conditions. In some cases, however, visual housings are used with kitchen appliances or electrical devices that generate heat.

If temperatures higher than 70°C are likely, ABS is not the best choice.

PC and PPO tolerate high temperatures much better, even up to 125°C. PC-HT goes even higher.

PC/ABS is a better choice that ABS.

You need to establish the maximum temperature your product is going to be stressed in, choose a material suitable for that range and design the product while bearing in mind how the temperature affects its mechanical properties.

In addition to short term service temperatures, you must consider that if the product is constantly subjected to high temperature in the long term, creeping will speed up, and stress corrosion and, in some cases, thermal degradation will appear.

Static loading and high temperature are an exceptionally challenging combination for plastics, especially amorphous grades.

It is easy and informative to compare the behaviour of different plastic materials by heating them in an oven. Plasticprop samples suit this purpose well.

Read more about the effect of elevated temperature here.

Visual appearance

If your product is well designed and properly molded with a proper tool, its visual quality should not differ much whether it is made of ABS, PC or ABS/PC. They all should come out straight and glossy.

ABS is the easiest to mold. Its tendency to warp is low. Burrs are minimal. Surface gloss is excellent and has a “drier” feel than that of PC .

PC requires a higher molding temperature and is a little more challenging to produce. For a professional manufacturer, this should not be an issue.

PS can be used for making a visually appealing product as well. The rattling echo of the components, however, does not increase the perceived quality.

Perhaps the main difference between the three comes with scratch resistance; in the long term use, ABS is better than PC .

Surfaces can be textured, glossy or satin-like matte. Small and appealing details can be etched or lasered on the mold cavity.

The surface finish of the backside of the component is often forgotten. Remember to specify it when going through the details of the tooling.

UV resistance

Long term exposure to direct sunlight affects plastic materials both mechanically and visually.

The strength and ductility of the material is decreased.

Visually UV-light leads to crazing and changes in the colour of the product. It may, for an example, turn from white to yellow.

Fluoroplastics are the only material group than can be considered intact to UV light. With all other plastics, UV light is an issue.

When designing a visually demanding product you have to consider the UV light effect on the colour of the product, including in indoor use. Both the sunlight that penetrates the window and many indoor lights emit UV rays. It is common to see light-switches, printer lids or smoke alarms that have turned from pure white to nicotine yellow.

ASA is commonly known to resist UV light better than ABS, and it is used in car wing mirror housings without any special coating to protect it from UV light. There is, however, typically a black rim around such components. This way it is difficult to notice the slight change in colour compared to the painted parts.

Interestingly, PC/ABS has a slightly better UV resistance than PC or ABS, but it cannot be recommended for products that are placed outdoors for longer periods of time. The UV resistance of PPO is not good either. Practically all amorphous materials can be painted with UV-protective paint or lacquer.

Always opt for grades (material and colourant) that are specially modified with UV stabilizers and blockers. “General purpose grades” of any material are more likely to lead to problems.

Try to find reference cases of materials that have survived well under corresponding conditions and opt for those. Dark colours are better than light ones because they prevent UV rays from penetrating deeper into the material.

Important: The use of UV stabilized material is not enough – the colourants must be UV-stabilized as well.

Read more about UV resistance here.

Performance in low temperature

When operating in a cold environment, plastic components tend to become harder, stronger and stiffer.

However, they also lose some of their toughness, turn more brittle which affect their impact resistance.

This is especially likely to happen when operating below the material-specific glass transition temperature, Tg.

If your product is likely to be used in cold conditions, and especially if it is subjected to impacts, make sure its toughness is sufficient in the expected service temperature.

Low service temperature is one of the advantages of ABS.

PC/ABS blend is a better choice that PC.